Series Mining Pump Anti-Wear Long Work Life Hard Metal High Chrome

Cast Iron Pump Parts

Introduction

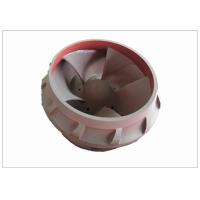

The main wet parts of our slurry pumps are made of high chrome

alloy(made of Cr 26-28%, with hardness HRC60+) wear resistant

metal, and it's made as per standard which can be interchangeable

with famous brand pumps.

We can also accept OEM services, which means we can produce it as

your own design.

Features:

1. The wet parts for slurry pump are made of wear-resistant

chromium alloy.

2. Slurry pump's bearing assembly use cylindrical

structure,adjusting the space between impeller

andfront liner easily, they can be removed completely when being

repaired. Bearing assembly use

grease lubrication.

3. The shaft seal could use the packing seal, expeller seal and

mechanical seal.

4. The discharge branch can be positioned at intervals of 45

degrees by request and oriented to any

eight positions to suit installations and applications.

5. There are the drive types, such as V belt drive, gear reducer

drive, fluid coupling drive, frequency

conversion drive devices for the slurry pump.

6. Wide performance, good NPSH and high efficiency. The slurry pump

can be installed in multistage series to meet the delivery for long

distance.

| Material | Code | Specification | HRC | Pump spare parts | Application |

| Hard metal | A05 | High chrome white iron, Cr 25~30% | ≥56 | Impeller / Liner | Used for higher wear condition with PH between 6 to 12. Such as

slurry pump, Dredging pump. Widely used in mine, coal, power plant,

dredging, steel, building material. |

| A07 | High chrome white iron, Cr / Mo alloy. | ≥59 | Impeller / Liner | Used for higher wear condition with PH between 6 to 12. Such as

slurry pump high abrasive. Widely used in mine, coal. |

| A49 | High chrome,

Anti-corrosive Cr/Mo/Ni alloy | ≥42 | Impeller / Liner | Used for FGD(Gypsum slurry circulating)and other corrosive

application. |

| A33 | High chrome, wear resistant

Anti-corrosive Cr,/ Mo/ Ni alloy | ≥36 | Impeller / Liner | Used for Phosphorus chemical industry, Phosphorus gypsum slurry. |

| Rubber | R26 | Standard liner rubber. | ≥43HA | Liner | Have good wear resistance and erosion resistance. Used for pump

liner. Maximum particle size ≤10mm. Widely used in slurry pump

liner and FGD pump liner. |

| R08 | Standard impeller rubber. | ≥55HA | Impeller | Have good wear resistance and erosion resistance. Used for pump

impeller. Widely used in slurry pump impeller. Vertical pump parts. |

| R55 | Natural rubber | ≥46HA | Impeller / Liner | Have cut resistance, sharp slurries. Widely used in slurry pump

parts. |